QUALITY with CONFIDENCE

– Non-yellowing color fast aesthetics

– Asphalt Compatibility

– Best in class warranty

Bostik PRO-MS 50™ is a one-component, solvent free Silyl Modified Polyether Sealant. It demonstrates hybrid sealant properties such as color stability and long lasting elastomeric qualities for building envelop architectural grade applications. Primary applications include vinyl window perimeter sealing, fiber cement board, engineered trim board, flexible flashing materials, metals such as Kynar coated metals, Bondarized and galvalulme, and siding applications.

• ASTM C920, TYPE S, GRADE NS, CLASS 50, USE NT, A, O

• CARB and SCAQMD Compliant

• Meets VOC Requirements for OTC Regulation

• AAMA Compliant 713-10, 808.3-10

• US. Federal Specification TT-S-00230C, CAN/CGSB 19.13-M87

• Seals joints between most vinyl siding, fiber cement board (FCB), aluminum, most metals, and other common building materials.

• Interior and exterior bonds—transitional seal between building materials.

• Perimeter seals for windows, doors and other wall penetrations on vinyl, fiber cement board (FCB) and other siding materials.

• Metals such as Kynar coated metals, Bondarized and galvalulme and metal building construction and synthetic materials.

•Flexible Flashing materials

• Construction substrates have become complex and diverse by nature and origin. Substrate chemistries and structures can interfere with adhesive performances of the sealant. Adhesion to Substrate Pretest (ASP) is therefore MANDATORY to assess any adhesion and sealing characteristics — see Adhesion to Substrates Pretest section and see Installation Protocol section. This must be done pre-installation to avoid potential failures. Call Technical Service for more information about surface preparation and possible priming.

• Do not apply over damp, contaminated, loose surfaces (See Installation Protocol and Surface Preparation), old sealants or other foreign substances that may impair the adhesion bond. Avoid air entrapment.

• Dampness and substrates with high moisture will trigger extensive curing of the sealant within a very short period of time.

• Porous substrates such as, but not limited to, marble, limestone and granite might absorb components of the Bostik PRO-MS 50™ leading to staining of the substrate. ASP with sufficient aging is mandatory to assess this potential issue.

• Compatibility to copper-based substrates (i.e. flashing) can vary due to, but not limited to, age and joint size. Please consult technical services for details.

• The ultimate performance of Bostik PRO-MS 50™ depends on proper joint design and proper application with joint surfaces properly prepared (See Installation Protocol). Bostik PRO-MS 50™ is not recommended for joints with dimension less than or greater than what is recommended below. (See Installation Protocol — Joint Design section.)

T1764 - 05.19.14

• Bostik PRO-MS 50™ must not be used to seal narrow joints, fillet joints and nail face holes.

• Smearing and feathering Bostik PRO-MS 50™ over joints is not recommended.

• Bostik PRO-MS 50™ is not recommended for horizontal joints or traffic- bearing joints where abrasion resistance is required (walkways, driveways, runways, etc.). Please refer to Bostik 505™, Bostik 555-SL™ and Bostik 955-SL™ for this application.

• Bostik PRO-MS 50™ is not recommended for continuous immersion in water or any other fluid. When fully cured avoid exposure, even incidental, to fuels, chlorinated, acid and alkaline solutions. Bostik PRO-MS 50™ is not recommended for exterior or interior sealing below the waterline; please refer to Bostik 940™ Fast Set for marine applications.

• During the curing of Bostik PRO-MS 50™, do not expose to alcohol, acids or solvent-based materials.

• Lower relative humidity and temperature will significantly extend the curing time. Confined areas, deep joints and moisture barrier substrates may also affect the full cure time and extend it by many days. Apply sealant in ambient airtemperature of 40° F. and rising.

• Until the sealant is fully cured, do not expose the sealant to any mechanical stress. Uncured sealant will not respond properly to cyclic expansion and contraction of the joint specified for the cured sealant only.

• The surface of a Bostik PRO-MS 50™ seal when exposed to UV rays and sunlight will not yellow but over time its gloss may change. Bostik PRO-MS 50™ may remain tacky for a few hours and attract dust and dirt from the jobsite which may affect the appearance of the sealant. Check tack-free time to prevent dirt pickup.

• Bostik PRO-MS 50™ is not recommended for glazing applications. Bond line strength can be affected by UV rays through the clear material (glass, acrylic glass, polycarbonate, etc.).

• Bostik PRO-MS 50™ is not RTV silicone and therefore is suitable for painting with latex based paints. Paint chemistries and flexibility characteristics of the paint films over the sealant may affect wetting, adhesion and integrity of the paint layer; and it is therefore mandatory to pretest the paint or other coating over the Bostik PRO-MS 50™ to ensure the successful compatibility between the sealant and the paint/coating after a sufficient amount of time. See your paint manufacturer for specifications and limitations and call our Technical Service for more information. In general, oil-based paints are not recommended because of their poor elastic properties and because of their potential interaction with the sealant chemistry, which may create non-curing conditions for the paint.

Joint Design: Joint Design: In general, more joint movement can be accommodated in a thin bead of sealant than a thick bead. Bostik PRO-MS 50™ should be no thicker than 1/2" (12.7mm) and no thinner than 1/4" (6.4mm). In joints between 1/2" and 1", the ratio of sealant width to depth should be approximately 2:1. Sealant depth in joints between 1/4" and 1/2" should be 1/4" deep. Joints with dynamic movement should not be designed in widths less than 1/4". Surface Preparation: See limitations about surface preparation. Surfaces must be structurally clean, dry (no frost) and structurally sound, free of contaminants, including, but not limited to, dust, dirt, loose particles, tar, asphalt, rust, mill oil, etc. If substrate is

painted or coated, scrape away all loose and weakly bonded paint or coating. Any paint or coating that cannot be removed must be tested to verify adhesion of the sealant or to determine the appropriate surface preparation if needed. (See ASP section on next page for details.)

To remove laitance and any other loose material, clean concrete, stone or other masonry materials with non-alcoholic based solvent by washing, grinding, sandblasting or wire brushing as necessary. Do not use water to clean substrates. Dust must be thoroughly removed after cleaning.

Backer Rods and Bond Breaker Tapes: Bond breakers including, but not limited to, closed-cell polyethylene backer rods are used to control depth of the sealant bead, provide a firm tooling surface and avoid three-sided adhesion. Where the depth of joint prevents use of backer rods, a polyethylene strip or tape must be used as a bond breaker to prevent 3-sided adhesion. Do not prime or damage the surface of the bond breaker. Refer to instructions given by rod and tape manufacturers for the correct backer rod and tape size related to joint size.

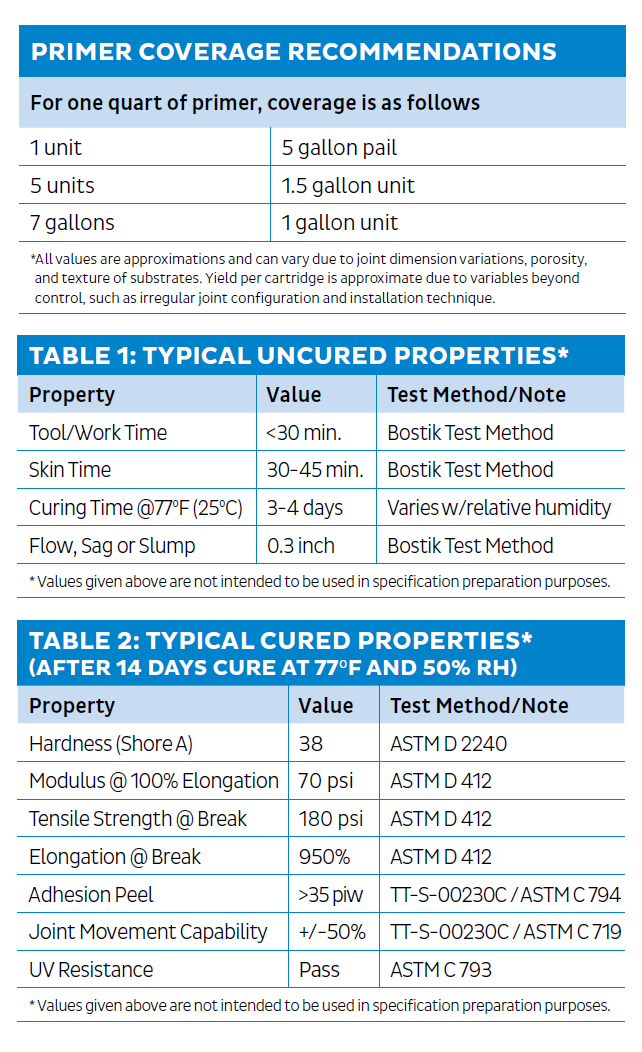

Priming: In general, application of Bostik PRO-MS 50™ does not require priming the substrates. However, some substrates may require a Bostik primer. It is the user’s responsibility to check adhesion of the cured sealant on typical test joints at the project site before and also during application as weather conditions may affect the adhesion results (See ASP section on next page). Refer

to Bostik Primer product data sheet or call Technical Service for proper selection and application of Bostik Primers.

Tooling: Bostik PRO-MS 50™ comes ready-to-use. Cut spout or tip to desired bead size. Apply moderate pressure to break seal inside the nozzle. Apply by using a professional caulking gun. Use opened cartridges and sausages the same day they are opened. Apply Bostik PRO-MS 50™ in a continuous operation using positive pressure to the bottom of the joint to properly fill and seal the joint. When applying, avoid air entrapment and overlapping. Tool the sealant before the skin forms with adequate pressure to spread the sealant against the backup material at the bottom and sides of the joint. A dry tool with a concave profile is recommended for that operation. Do not use water or soapy water for this operation. Avoid smearing and feathering of the sealant to allow full performance of the cured seam. Excess sealant should be drywiped or joints should be properly taped.

Cleaning: After dry-wiping uncured sealant from substrates and tools, remaining uncured sealant can be removed by using Xylene, Toluene or similar aromatic solvents. Please refer to the MSDSs provided for these solvents before use. Bostik Hand Towel and Specialty Sealant Remover™ can also remove uncured sealant. Cured sealant is usually very difficult to remove without altering or damaging the surface to which the sealant has been misapplied. Cured sealant can be removed by abrasion or other mechanical means (scrapers, putty knives).

Curing Time: Bostik PRO-MS 50™ is a moisture cure sealant. On wood, with ambient air at 50% relative humidity and at 73°F, Silyl Modified Polyether sealants will generally skin in less than one hour and cure 1/16 of an inch per day. Lower temperature and lower relative humidity will significantly increase the skin time and cure time of a Silyl Modified Polyether sealant.

Painting and Coating: Bostik PRO-MS 50™ is not RTV silicone and therefore is suitable for painting with latex-based paints. Paint chemistries and flexibility characteristics of the paint films over the sealant may affect wetting, adhesion and integrity of the paint layer, and it is therefore mandatory to pretest the

paint or other coating over the Bostik PRO-MS 50™ to ensure the successful compatibility between the sealant and the paint/coating after a sufficient amount of time. See your paint manufacturer for specifications and limitations and call our Technical Service for more information. In general, oil-based paints are not recommended because of their poor elastic properties and because of their potential interaction with the sealant chemistry, which may create non-curing conditions for the sealant. Do not paint over the polyurethane sealant until it has fully cured.

Maintenance: textIf the sealant becomes damaged, replace the damaged portion by removing the old sealant completely, cleaning the surfaces and reapplying a fresh and appropriate amount of new sealant in accordance with the directions and information contained in this data sheet.

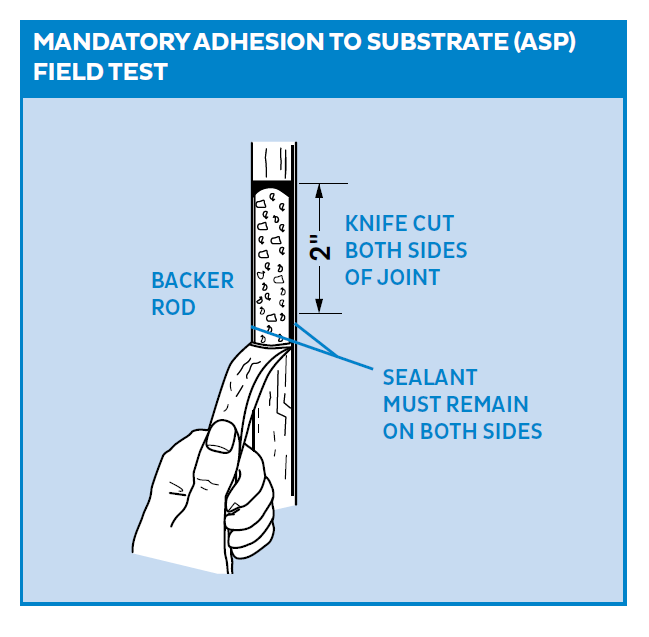

A hand pull test must be run before the job starts and at regular intervals during the job. It must be run on the job site after the sealant is fully cured, usually within 7 to 21 days. (Adhesion may develop fully after at least 14 days.) The hand pull test procedure is as follows:

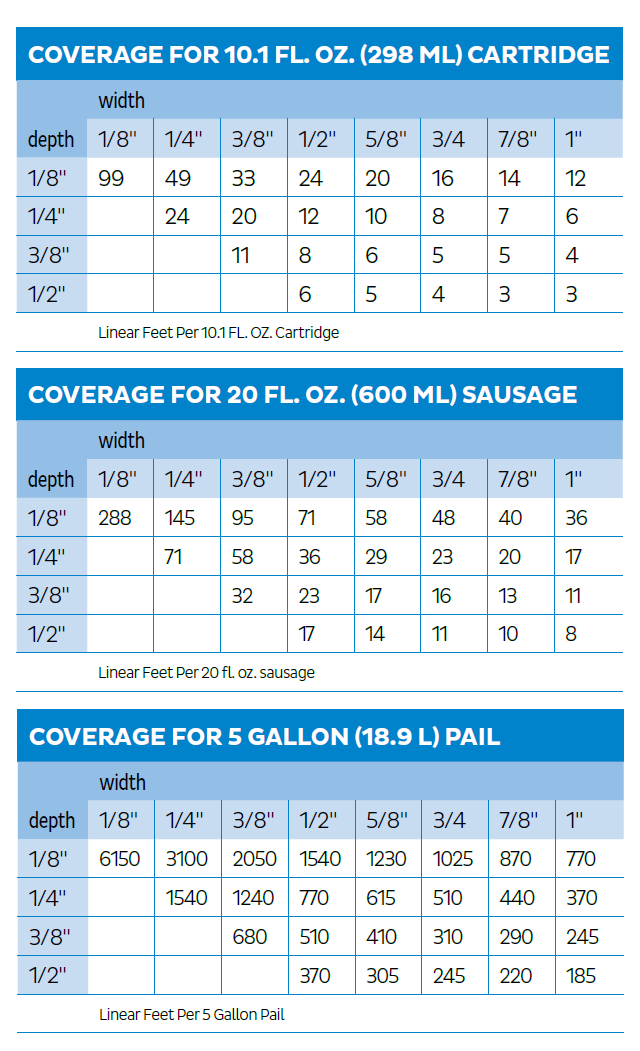

10.1 fl. oz. Cartridges, 24 Cartridges/Case

20 fl. oz. Sausages, 12 Sausages/Case

Shelf life of PRO-MS 50™ must be checked prior to using the product; do not use past its shelf life. Caulk past its shelf life may not perform or adhere as described by this data sheet. High temperature and high relative humidity may reduce significantly the shelf life of polyurethane sealants. If you are unsure of the expiration date of your Bostik product, please call customer service at 1-800-7/BOSTIK (1-800-726-7845) to check if the product is still within its shelf life.

White Medium Bronze Stone Terra Cotta

Bronze Desert Tan Limestone Antique White

Light Gray Aluminum Gray Black Capitol Tan

Available from authorized Bostik distributors. Go to www.bostik-us.com and check on our distributor locator for the closest distributor in your location or call customer serviceat 1-800-7/BOSTIK (1-800-726-7845).

Please refer to the MSDS for First Aid Information. Most current MSDS’s can be found on Bostik’s website at www.bostik-us.com or call customer service at 1-800-7/BOSTIK (1-800-726-7845).

TECH SERVICE phone number: 1-800-7/BOSTIK (1-800-726-7845). Field visits by Bostik personnel, Bostik manufacturer representatives or Bostik authorized distributor personnel are for the purpose of making technical recommendations only and not for supervising or providing quality control on the jobsite.

COMBUSTIBLE. HARMFUL IF SWALLOWED OR INHALED. CONTAINS POTENTIAL SENSITIZER. MAY CAUSE ALLERGIC SKIN OR LUNG REACTION. MAY IRRITATE EYES, SKIN AND RESPIRATORY TRACT. Methanol may form during curing. Do not breathe fumes. Do not get in eyes, on skin or on clothing. Do not swallow. Use only in a well-ventilated area or wear mask. Keep away from flames or sparks. Wash thoroughly after handling. Store container in a cool dry area with lid tightly sealed. Do not reuse container. KEEP OUT OF THE REACH OF CHILDREN.

Contains Petroleum Resins, Diisodecyl Phthalate (DIDP), Methylene Diphenyl Isocyanate (MDI), Quartz Silica. Methanol may form during curing. If in eyes or on skin, rinse with water for at least 15 minutes. If on clothes, remove clothes. If breathed in, move person to fresh air. If swallowed, call a Poison Control Center or doctor immediately. Do not induce vomiting.

Use dry chemical, carbon dioxide, or foam. Water spray (fog).

135 ºF (57.2 ºC)

The Limited Warranty for this product can be found at www.bostik-us.com/resource-center/warranties or by calling 1-800-726-7845 (choose option 2, then option 2 again). TO THE MAXIMUM EXTENT ALLOWED BY LAW, BOSTIK DISCLAIMS ALL OTHER EXPRESS OR IMPLIED WARRANTIES, INCLUDING WITHOUT LIMITATION WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. UNLESS OTHERWISE STATED IN THE LIMITED WARRANTY, THE SOLE REMEDY FOR BREACH OF WARRANTY IS REPLACEMENT OF THE PRODUCT OR REFUND OF THE BUYER’S PURCHASE PRICE. BOSTIK DISCLAIMS ANY LIABILITY FOR DIRECT, INCIDENTAL, CONSEQUENTIAL, OR SPECIAL DAMAGES TO THE MAXIMUM EXTENT ALLOWED BY LAW. DISCLAIMERS OF IMPLIED WARRANTIES MAY NOT BE APPLICABLE TO CERTAIN CLASSES OF BUYERS AND SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU. It is the buyer’s obligation to test the suitability of the product for an intended use prior to using it. The Limited Warranty extends only to the original purchaser and is not transferable or assignable. Any claim for a defective product must be filed within 30 days of discovery of a problem, and must be submitted with written proof of purchase.

This product contains a chemical(s) known to the State of California to cause cancer and/or birth defects or other reproductive harm.